TECHNOLOGY

How GlideWear™ Works

GlideWear™ is a highly versatile fabric designed to protect skin and soft tissue from the effects of friction and shear forces. It can be strategically integrated into a variety of products for medical, athletic, and other uses where friction management is desired.

Clinically Proven EfficacY

The slippery, low-friction interface between GlideWear’s dual fabric layers reduce friction forces by 50% to 80%, protecting target areas from dangerous shear forces which can be the major factor responsible for soft tissue damage.

Durable Performance

It is durable, low profile, lightweight, double-layered, gas and vapor permeable, and its two-way stretch allows it to conform to body contours.

Customizable & Affordable

Wound care, bedding, orthotics & prosthetics, wheelchairs and athletic wear are just a few examples of products enhanced by the addition of GlideWear™ at the clinical, consumer, or OEM level.

GLIDEWEAR™ FABRIC

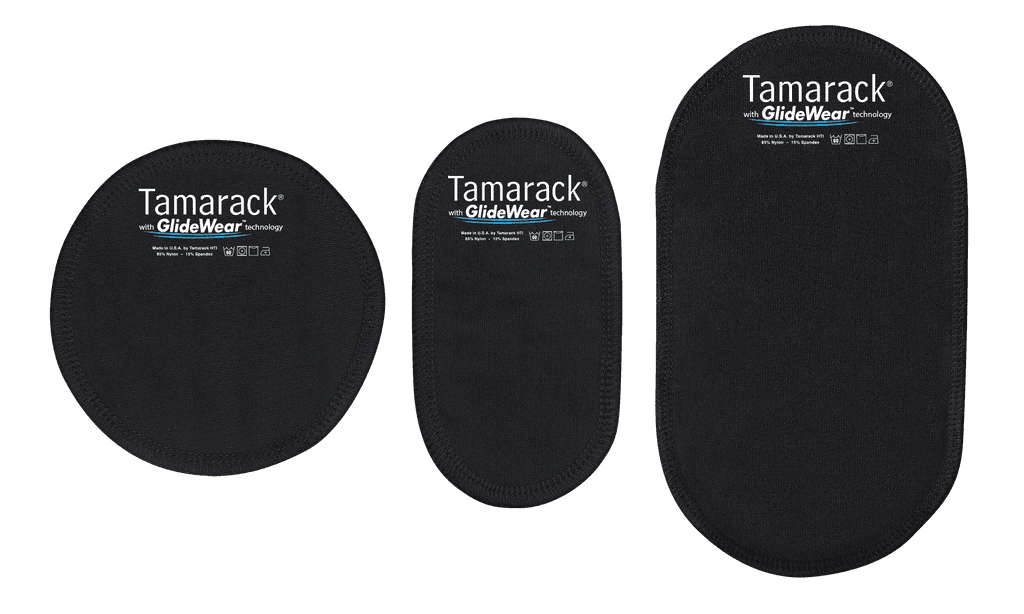

Bulk Pre-Ply Fabric

Integrate professional friction management into your own product lines with our bulk pre-ply fabric that can be custom cut to fit your needs. A patch or panel of GlideWear™ sewn into a location where troublesome rubbing will occur reduces the damaging shear & friction forces by up to 80%, allowing you to strategically protect skin and soft tissue. GlideWear™ is comfortable, durable, and clinically proven.

pre-ply Fabric

Endless Applications

Ideal For

Placement of our patented GlideWear™ low-friction fabric minimizes shear and friction in targeted areas by allowing the skin to glide back and forth with bone movement. GlideWear™ reduces friction forces by 50% to 80%.

Prosthetic Liner Patch

Prosthetic Brim Sheath

Cushion Covers

Headrest Covers

Pillowcase

Protection Pads

Veterinary Sleeve

TESTIMONIALS

What GlideWear™ users are saying

“Using GlideWear garments for my daughter reduced bandages by approximately half, saving about $5,000/month. And because fewer bandages are needed, GlideWear makes (my daughter) more comfortable — they can move more freely and wear fewer layers in hot climate.”

Gabriella McCann

Mother of a daughter with EB

“Tamarack's friction reduction products will improve the quality of life of millions of people dramatically. Marty Carlson's genius enthusiasm for friction management give us the solutions our patients have been waiting for”

Heinz Trebbin OTM, CPO, MSc

University Don Bosco El Salvador

“I love the Glide Wear technology. When chosen for the right individual, it’s great to reduce the amount of shear force in the transfer, and I have found it to help the “active” crowd who continually moves and shifts in the chair without pressure relieving. Great cushion, great covers.”

Rob Lins, ATP, RTS

Home MediService Inc

“Best underwear ever!!! Love this stuff!! I sit in wheelchair all day. I have been T6 paraplegic for 30 years. I have (been using) GlideWear underwear for a month. There is no sign of redness since using GlideWear. I sit on a Roho cushion and normally the cushion gets hot and moist. But not with the GlideWear, somehow the material doesn't build up heat or moisture. Also the GlideWear doesn't wrinkle. Before GlideWear I was sitting on cotton underwear and they would wrinkle and be moist.

I can't say enough about the GlideWear. I really love this stuff.”

David Roos

GlideWear User

“Great way to keep the bed sores away! My mother is in an assisted living facility and also has a lot of problems with her feet. This leads to her spending a lot of time in a wheelchair or in bed. Every time I see her she complains about bed sores and her feet hurting. It hurt to feel so helpless where I could do nothing but complain to management that she was getting bed sores. Then I got these! I gave it a few months to give the most accurate review and I will say they are amazing. Her bed sores are pretty much completely gone and she does not complain about her bottom hurting. I would highly recommend these to any one that knows someone in assisted living.”

Anonymous

INDUSTRY SOLUTIONS

In 2019, the Swedish helmet safety company, Mips, acquired the IP for GlideWear™ Technology and began exploring its potential for use in their industry-standard helmet technology.

Tamarack retains rights to sell and use GlideWear™ for several medical and specialty applications.